The Brand New F62 and F77 Project: Re-creating a Keyboard That has not Been Made in 25+ Years

11 Nov 2015

The greatest keyboard revival project in current memory. This is the project to revive and fully re-create the IBM 4704 terminal keyboards. Lead by Ellipse this is a faithful recreation of the F62 and F77 4704 terminal keyboards.

This may seem a little unusual but this is being done for good reason. These 4704’s are model F capacitive buckling springs. In a variety that is extremely hard to find. They are being made in two varieties the 62, and 77 key versions. Although similar to the ever, and increasingly popular model M. The capacitive pcb more commonly associated with the Model F, adds another dimensions to the switch feel.

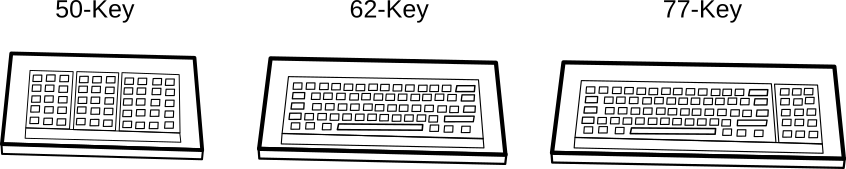

To understand the root of this project I will go over a little bit of the history. Pretty much all information about the 4704’s was originally collated by kishy which is why the 62 key 4704 is generally referred to the Kishsaver. Pretty much all of this information is coming from kishy’s website. It was not solely Kishy as I believe it was a joint project to actually track down one in the first place. It is a very hard to find keyboard at the moment because it is quite old and I’m not quite sure how many were made. They were originally used by tellers, back-office or administrative personnel. I imagine if the 62 key model was being used, it would have been used in conjunction with the 50 key 4704 which is an oversized numpad. The fact that this keyboard exists is slightly confusing to me as it seemed IBM’s style in the 80’s was more in-line with the unsaver keyboard. It has been fairly recently where we are seeing a huge popularity boost of the 60% and even 40% style boards. The kishsaver is an enigma of old keyboard design because of it’s size.

4704 Keyboard Family

Crude but characterful trace by me.

Crude but characterful trace by me.

Why the kishsaver?

The main interest is the fact that it is a 60% sized keyboard in a switch type that is not easily transferred into custom projects. For this reason the Kishsaver is really one of a kind, as it is something that is a sought after form factor today. There are many articles detailing the fact that people still enjoy using the Model M and F keyboards today. But the Kishsaver includes both the switches that are loved from those boards, and the increasingly popular 60% size, this is just something that has not been available until now.

The first 4704 62 key was shown by Kishy but there was a subsequent discovery by tinnie that got a few more in circulation. Getting one today you are either going to be extremely lucky coming across one at an electronics recycler, or you would be buying one for a high price in the after market. This alone makes it such an incredible project. Without this happening, it is would only get increasingly harder to get one of these excellent keyboards.

I have been focusing on the 62 key variety, but the 77 is also a very rare keyboard. Even more so than the Kishsaver I can’t say that I have come across one of these F77’s in the wild at all, before the introduction of this project. What Ellipse is doing is producing more of the these 4704 terminal keyboards in 2015. Unicomp is still producing Model M’s to this day, but no one has produced a Model F in possibly 25+ years.

This is not at all an easy project to take on. Unlike a cherry or alps switch, the switches are not single units and so not produced in the same way. All the custom moulds for each part have to be recreated. Designs and schematics for the PCB, all need to be created. At the end of this project there will be fully programmable new F62 and F77 keyboards with xwhatsit controllers and firmware. This is keyboard history in the making. Getting a newly made F62 or F77 is incredibly unlikely to happen again.

This is a custom keyboard project on a scale that I haven’t seen before. I really wanted to know why Ellipse would do something like this. It just seems beyond the call of duty of a keyboard enthusiast.

Questions for Ellipse:

What drew you to this project? From all the people in the keyboard community there is a lot of excitement about the Kishsaver and rarer model f’s. But no one (until quite recently) has really been able to do a ‘custom’ buckling spring. It seems incredible that you have taken this project on and are progressing so fast.

I am a big fan and collector of the IBM buckling spring keyboards. I have tried Cherry MX mechanical keyboards and regular rubber dome ones and they do not compare! My very first keyboard was a Model F. The first family computer was an IBM PC (5150) or IBM PC XT (not sure the exact model) and its IBM Model F XT keyboard. These days I use the 122 key Model F keyboard as my daily driver thanks to Soarer’s great work with his converter and Fohat’s guide to refurbishing and adjusting the F122 layout to more of a 1391401 Model M ANSI layout.

Last year (2014) xwhatsit helped me to bring his Model F keyboard controllers to mass production and assembly in China at a significantly lower cost. I spent a while looking for more F62 Kishsavers and F77 keyboards to no avail; I was just able to find some F77 keyboards including one brand new one. Given the high demand for Kishsavers and 77-key Model F keyboards and the non-existent supply, I looked into what it would cost to bring these great keyboards with metal cases back into production, working on the CAD files and discussing ideas with a number of very smart people including professional engineers, PCB designers, and product designers, some of whom have contributed to the DT/GH/reddit forums. I was also inspired by the significant interest and discussions on the forums regarding bringing back the Model F buckling spring keyboard.

This project is definitely not a one man show - I could not have done this project without the help of so many community members, especially xwhatsit for inventing a reliable capacitive controller replacement for Model F keyboards, as well as others whom I have not yet asked if they would like to be publicly recognized. I have learned a lot along the way about manufacturing, PCBs, materials, micrometer measurement, CAD (computer aided design), and about the specifications of Model F keyboards.

This is a unique project in that it is the first one to bring back Model F buckling spring technology, which has been out of production for essentially 25+ years (with the exception of some low volume refurbishings/repairs primarily from new old stock and reproduction PCBs in the mid-90s at Lexmark). The buckling spring patent expired long ago, opening the door to “generics” but no projects involve brand new buckling spring keyboards made from 100% new stock and made in 2015. I had to pay for all the tooling, CNC milling and molds. Another forum member pointed out that the Cherry MX and other custom keyboard projects have lower production costs as the individual key mechanisms are pre-made, unlike Model F components.

Do you see it as a perfect keyboard? This is a faithful reproduction I was wondering if there is much reasoning behind not changing much.

I would say Model F keyboards are great, though I have not yet received the completed prototypes, which are expected to arrive from China in a few weeks, so I can’t say whether my Model F 2015 keyboards will be great. When I get them I will be carefully testing them to make sure they live up to the originals and to my quality standards. The intention of the project was to faithfully recreate the 77 key and 62 key keyboards, whose designs are both proven and in high demand as they are, without any alterations. Changing things around would have brought both positive and negative feedback and would have been considerably more costly to make a series of prototypes and test them. I do not have much CAD skill for that kind of work and actually taught myself CAD for this project.

Are you finding anything that you would have liked to have changed?

I would liked to have changed the cases to being made with die casting instead of CNC milling. There are no economies of scale with CNC milling as each cover piece is made one at a time and it takes a set number of machine-hours per piece. Die casting would have brought more economies of scale (and therefore a lower price!) but would have required high 100s/1000s of units to be economical due to the significantly higher tooling costs of tens of thousands of dollars more than CNC milling.

Have you been working on it longer than when you went public with the project?

Yes I have been in talks since April with a number of product design experts, engineers and forum contributors, including my contacts at a major factory in China.

Is this the first of multiple projects? Could you do something like a beamspring or topre board? I can see beamspring being revived in the same vein as this project.

I am making some extra Model F barrels/flippers/springs and other parts that people can order separately if they’d like to create their own Model F related projects without the need to pay for all the tooling. I will not be working on beamsprings anytime soon. I have done repair work on my own beamsprings and their internal mechanisms are extremely fragile and prone to interference from dirt/dust. On the other hand Model F keyboards were designed to be much more robust and reliable. A great quote from one of the forum contributors is that beamspring keyboards were built up to a spec, not down to a price point. I hope someone else is inspired to take on beamsprings, but the tooling costs alone would be astronomical - probably $50,000 or more plus the significant variable per unit production costs.

What’s your background? Does it have anything to do with vintage keyboard production?

I have had a great interest in computers from a young age and have done a lot of typing on Model F keyboards. I have taken them apart and repaired/restored a number of them. But no related background for me; I am not a professional programmer or CAD person. The professional and/or enthusiast-level background of those who have helped me with this project include programmers, PCB/hardware designers, engineers, product designers/inventors, and other Model F keyboard fans.

The keycaps seem to be an issue at the moment. It’s not that unicomp doesn’t exist, its just their apparent lacklustre approach to buckling springs. Would you be able to aid in the new production of BS caps? Or is this just entirely different?

The keycaps from this project will be sourced from old IBM keyboards (for those who want to borrow caps from their old keyboard) as well as Unicomp for those who want new keys. Tooling and quality control for key caps would take a significant amount of additional funds and time which are unfortunately out of budget for my project. My suggestion for those taking on Model F keycap production is to make them up to the standard of the original IBM PC XT keyboard: “rough” textured tops that will not wear down as quickly as Model M keycaps, deep/black/bold dye sublimated legends, and one-piece (integrated cap and stem) instead of the two piece Model M design.

Its not easy to reserve judgement on this project I find myself taken away by the scale of it.

Yes the project certainly was one of the more ambitious ones out there, and I could not have accomplished this goal without the help of many individuals in different professional / enthusiast capacities as mentioned above.

Are you still currently on track for the December ish date?

Yes - my intention is to put whatever orders come in by early December so that they can be here by Christmas ideally, though this may prove too ambitious. The major risks with this project is that the prototypes are not up to standard and may require some slight adjustments to the design, as well as the capacitive flippers not being of a suitable resin material, as well as quality control of the finished products which are all being made overseas. I asked the factory to mail me a few of the new prototype injection molded barrels and flippers ahead of the full prototypes to minimize the delay to the project from needing to altering the flipper resin if it proves to be not usable. After receiving and thoroughly testing the prototypes later this month, I expect to post some photos and videos and allow anyone in the NYC area to meet up and try out the keyboards. For more information on the project and to ask questions and stay in touch with updates, please check out the Deskthority.net and Geekhack.com forum threads here:

If you are interested please fill out the Google Docs form here: https://docs.google.com/forms/d/18jlh9q … w/viewform

Also feel free to PM me on the Geekhack and Deskthority forums. My user name is Ellipse. Registration on the forums is free and they are great communities to be a part of.

I do hope that these keyboards survive the test of time. So many products people buy today develop issues in a few months’ or years’ time and are meant to be disposed of; it is great to be able to buy something made today that you can use every day and it will be there for you to use 10, 20, 30 years from now. I hope this F77/F62 project will be like that. I do not want to compromise a project like this by lowering standards and cutting corners to make it inferior to an original because it is something I want to be able to use and something that is on par with the original Model F keyboards that I use daily - that is why I expect to end up spending $50,000 or more on this project for materials and production processes that meet or exceed original standards and tolerances, including lots of metal!

I will post a link on the forums right after the order forms open up, so those keeping up on the forums will be first to know about it. I expect to assign serial numbers just about in the sequence of receiving the orders.

The $325 price has been finalized for the “bring your own keys” crowd. The keyboards will be assembled in China at no extra charge, and I will do final testing/QC on each keyboard. The cost of keys will be passed along from whatever Unicomp charges, which is about $25 and up depending on what options you would like (split shift, black blank keys, APL keys, RGB modifiers, F1 etc. front printing on the numbered caps, etc.). I will do a group buy to ship and install all the keys for those interested (factory installation in China will be no extra charge). I also have 5 sets of original used Model M keys available and I hope to get more if there is demand for it.

Final Thoughts

It makes sense that Ellipse has done a more faithful re-creation, as this is uncharted territory. Doing this re-creation is an incredible feat which just seems incredibly that it has actually happened. Most questions of “Can I make a custom buckling spring keyboard?” are met with “no not really”. The future is now uncertain and the answer to that question could be “possibly”.

This project is incredibly interesting for the community and whoever has an interest in old keyboards. It is most likely going to be a one time deal and you will have a keyboard that is going to be in usuable condition for a long time. This is not a usual GB and I think the end product will be satisfactory. Ellipse along with others have put a lot of effort into getting this to where it is. It is both something for the general enthusiast and the collector who might want a new version of the kish to go alongside the original.

If you are interested fill out the interest check form for the new F62 and F77.

Stay up-to-date with whats happening at either link:

Typed on HHKB Pro 2